Issues by Water Year: 2010

After more than three years of operation, ongoing issues continue to ebb and flow, such as some significant water quality challenges on Buckhorn that have corrective action in process.

Water Year 2010 Annual Meeting

The annual coordination meeting to discuss Buckhorn Mine’s Water Year 2010 data took place at the Eagle Cliff Grange on the bank of the Kettle River on March 15th. Annual monitoring reports were submitted to the agencies a few weeks prior to the meeting. The purpose of the annual meeting is to review a summary of the previous year’s monitoring data, discuss the adequacy of monitoring plans and recommend any modifications that might be needed. OHA opened the meeting with a presentation of our analysis of the monitoring data, and followed up with a presentation and the independent review by Ann Maest of Stratus Consulting, which laid out our concerns regarding the company’s analysis. OHA also raised concern over contaminated mine leakage and offered suggestions to address the issue.

OHA submitted a memorandum outlining changes to the Adaptive Management Plan we recommend and a list of actions that would improve the environmental reporting and performance of the mine. A separate memo was also submitted regarding Kinross/Crown’s failure to apply the required shotcrete to potentially acid generating (PAG) mine walls.

Kinross began their presentation with an overview of how much they contribute to the community with jobs and donations and how much gold has been produced. Next, they provided an overview of the capture zone issue, the water treatment facility and surface and ground water quality. Prior to the annual reporting, Kinross adamantly maintained that the capture zone was effectively intercepting all mine contaminants. At the annual meeting, Kinross consultant, Golder Associates, presented quite another story. After rerunning the groundwater model, it is clear that four monitoring wells in the North Lookout Fault-3, east of the mine, are outside the capture zone and that it could take years for the contamination to dissipate. Mine contamination has also leaked west of Buckhorn into the surface water of South Bolster Creek.

OHA Recommended That…

Operational Changes should be Documented:

Adaptive management will continue to play a critical role in mining operations. In fact, some of the most important operational changes that have taken place over the past year are not included, or are minimally mentioned, in the annual reporting. For instance, the renovation and upgrade of the treatment facility has greatly improved effluent discharge, thereby reducing downstream impacts; however, it is not discussed in any detail in the annual reports.

Unless the changes that have taken place are documented, future mine staff and regulators will only have a tangential understanding of how and why things are done the way they are done. This is an inadequacy of the Adaptive Management Plan (AMP). OHA recommended that a provision be added for annual reporting to include an explanation of the issues the mine has addressed over the year as well as the proposed or implemented solutions. Kinross and the agencies agreed with OHA that annual reporting will now include major changes that have been implemented at the mine, including an explanation of reasons for instituting the changes.

Faults Should be Mapped:

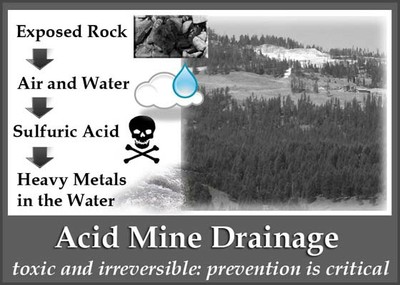

The network of fractures throughout the mine and underlying the facilities are more extensive than previously understood by mine officials. Contamination from the underground mine, and likely the waste rock/ore stockpile, travels underground through interconnected faults, bypassing the dewatering wells and ending up in ground and surface water down-gradient from the mine. The increase in sulfates could indicate the start of acid mine drainage. Nitrates from blasting have increased to the west, south, and east of the mine.

While the 2010 shotcrete inspection report failed to present the required volume and method of shotcrete application, it did reveal that additional faults exist, which have not been noted in any previous documentation. Understanding the location of new faults is well established as a critical factor in understanding the movement of contaminants.

The Development Rock Management Plan (DRMP) provides procedures for identifying PAG rock to secure safe storage and disposal. Part of that process includes mapping the location from which PAG is mined. OHA suggested that the quarterly reporting of development rock characterization should be modified to include quarterly mapping of PAG locations and mapping of any fault and fractures that are identified while mining. These reports would be summarized annually. This modification was accepted.

OHA also recommended that additional investigations of hydrologic pathways and faults on the mine site should be conducted. Studies could include additional pump tests, with response wells located across known or suspected faults; additional geophysical studies; and additional geochemical studies of water quality in mine sources and at stream and groundwater monitoring points. These suggestions are being considered.

Shotcrete is Needed To Prevent Acid Mine Drainage:

One very important aspect of the DRMP and AMP that is known to be highly effective has unfortunately not been implemented. Shotcrete inspection reporting reveals that only limited amounts of shotcrete were applied for PAG pacification last year and none in the previous year. Shotcrete is supposed to be applied to all PAG headings. For the last three years there have been increasing amounts of PAG rock and a corresponding greater amount of PAG headings. The application of shotcrete is not discretionary; it is a provision of the DRMP and AMP to be implemented because it would reduce the likelihood of Acid Mine Drainage (AMD).

The AMP for Development Rock states, “Shotcrete will be used to prevent air and moisture penetrating into blast fractures in the Damaged Rock Zone (DRZ), thus reducing oxidation and interaction between DRZ PAG rock and mine water. This shotcrete will also reduce oxidation (by limiting airflow) of DRZ PAG rock that remains exposed above the water table after the groundwater system has re-equilibrated. As part of the adaptive management plan, the extent of the shotcrete will be determined based on the mine engineer’s mapping of PAG rock, and water flows into the mine.”

Shotcrete creates a reasonably effective barrier to prevent AMD, whereas backfilled cement does not create an effective barrier. Backfilled cement performs a structural function so that additional mining can take place, but does not necessarily form a seal. As a result, water that infiltrates around and through the backfilled cement rock has a high probability of eventually picking up contaminants and spreading the contaminants into the ground and surface water. Unfortunately, for the past two years, little or no shotcrete has been applied. Kinross says that from now on they will apply shotcrete but they still think that no shotcrete is needed if cemented backfill fills the mine-shafts. This is not acceptable.

At the annual coordination meeting, OHA requested that Ecology require Kinross to go back and shotcrete all mine-shafts that contain PAG rock. Some of the shafts have already been filled with cement. OHA has asked that this cement be removed and shotcrete applied as required. The agencies will consider this request. OHA also requested that in the future, no cemented rock fill is placed until the PAG headings are properly sealed (shotcreted). OHA requested that PAG stockpile discharge monitoring occur monthly, a suggestion that will be implemented, as well as more often during spring runoff, which the company is considering.

Adaptive Management Issues

Kettle River Tailings Facility: There is a trend of increasing concentrations of nitrate, sulfate, and TDS in surface water; this should require Adaptive Management Plan action.